Ihemotoogwe ahụ dị oghere, yana arụmọrụ mkpofu okpomọkụ dị mma ma nwee ike ịkwalite ịdị fechaa nkemoto.Na mbụ, ogwe osisi moto na-esi ike nke ukwuu, mana n'ihi ojiji nke ogwe osisi moto, nrụgide na-adịkarị n'elu ogwe osisi ahụ, nrụgide dị n'etiti ya dịkwa obere. Dịka ihe ndị na-agbagọ na nke na-agbagọ nke igwe ihe si dị, akụkụ dị n'ime nke ogwe osisi ahụmotoe tinyere oghere ahụ n'ime oghere kwesịrị ekwesị, naanị obere dayameta dị n'èzí ka achọrọ iji mee ka akụkụ mpụta ahụ dịkwuo elu. Oghere ahụ nwere oghere nwere ike iru otu arụmọrụ na ọrụ ya dịka ogwe siri ike, mana enwere ike ibelata ibu ya nke ukwuu. Ka ọ dị ugbu a, n'ihi oghere nke oghere ahụmotoN'ime ogwe osisi, mmanụ oyi nwere ike ịbanye n'ime ogwe osisi moto ahụ, na-eme ka ebe okpomọkụ na-agbapụta dịkwuo elu ma na-eme ka arụmọrụ okpomọkụ na-agbapụta dịkwuo mma. N'okpuru usoro ugbu a nke chaja ngwa ngwa nke voltaji dị elu nke 800V, uru nke ogwe osisi hollow dị ukwuu. Ụzọ mmepụta ugbu a maka ogwe osisi hollow gụnyere isi ihe siri ike, ịgbado ọkụ, na nhazi agbakọtara, nke a na-ejikarị ịgbado ọkụ na nhazi agbakọta eme ihe n'ọtụtụ ebe na mmepụta.

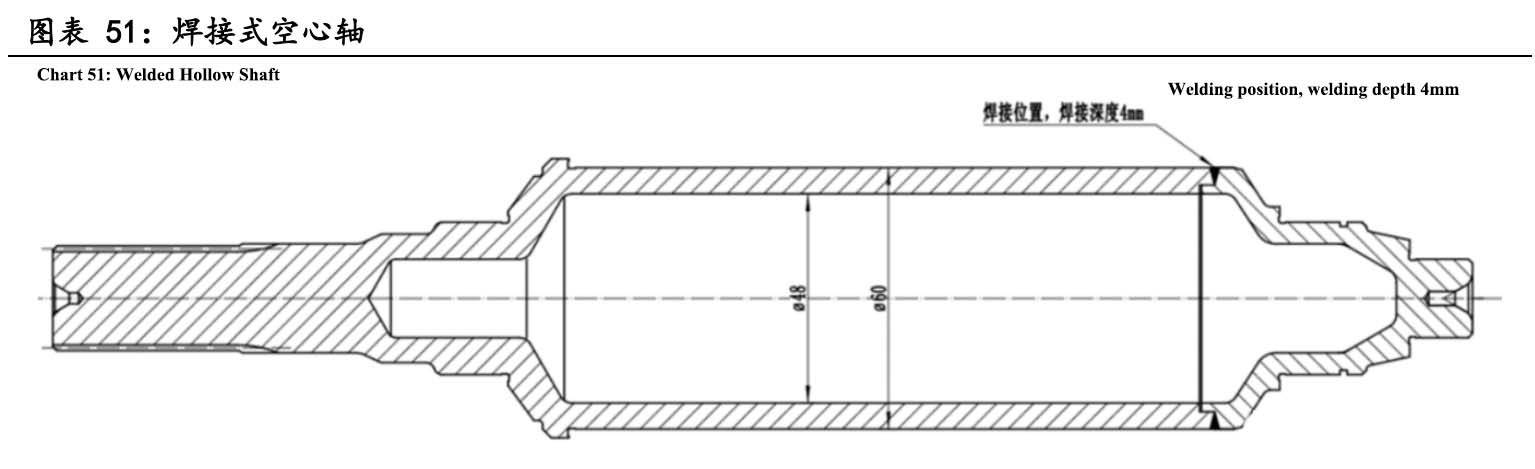

A na-enweta ogwe oghere a na-agbakọta nke ọma site na ịkpụpụta oghere dị n'ime ogwe ahụ iji nweta oghere dị n'ime steepụ, wee jiri ya mee ihe ma jikọta ya ka ọ dị ka ọ dị. Site na ịkpụzi oghere, a na-ejigide mgbanwe ọdịdị nke oghere dị n'ime yana nhazi ngwaahịa na ihe achọrọ maka ike ruo n'ókè o kwere mee. N'ozuzu, enwere ike ịhazi ọkpụrụkpụ mgbidi nke ngwaahịa ahụ n'okpuru 5mm. Ngwa ịgbado ọkụ na-ejikarị ịgbado ọkụ ma ọ bụ ịgbado ọkụ laser. Ọ bụrụ na ejiri ịgbado ọkụ n'ubu, ọnọdụ nke njikọ butt na-abụkarị ihe dịka 3mm mpụta ịgbado ọkụ. Site na iji ịgbado ọkụ laser, omimi ịgbado ọkụ na-adịkarị n'etiti 3.5 na 4.5mm, a pụkwara ikwe nkwa na ike ịgbado ọkụ ga-adị elu karịa 80% nke substrate. Ụfọdụ ndị na-ebubata ngwaahịa nwere ike nweta ihe karịrị 90% nke ike substrate site na usoro njikwa siri ike. Mgbe emechara ịgbado ọkụ nke ogwe oghere, ọ dị mkpa ime nnwale ultrasonic ma ọ bụ X-ray na obere nhazi na ịdị mma nke mpaghara ịgbado ọkụ iji hụ na ngwaahịa ahụ na-adị n'otu.

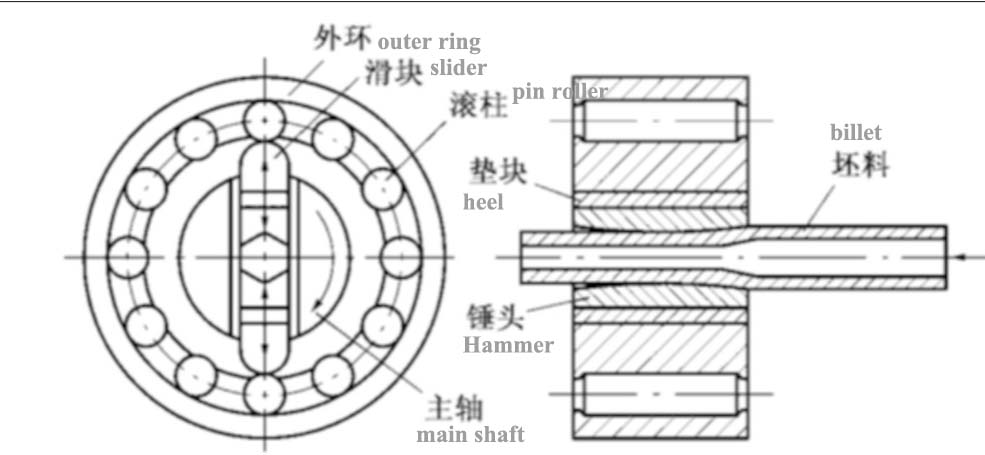

A na-eji ngwa mpụga dị n'ime oghere ahụ emepụta oghere oghere agbakwunyere, nke na-eme ka akụkụ ime ahụ nwee ike iru oghere dị n'ime ogwe ahụ ozugbo. Ugbu a, a na-ejikarị ụdị radial forging na ụdị rotary forging eme ihe, a na-ebubatakwa ngwa ahụ karịsịa. Ụdị radial forging bụ ihe a na-ahụkarị na ngwa ụlọ ọrụ FELLS, ebe ụdị rotary forging bụ ihe a na-ahụkarị na ngwa ụlọ ọrụ GFM. A na-enweta ụdị radial forging site na iji hama anọ ma ọ bụ karịa symmetrical na ugboro ole karịrị 240 feats kwa nkeji iji nweta obere mgbanwe nke tube oghere efu na nke na-apụta kpọmkwem. Ụdị rotary forging bụ usoro nke ịhazi ọtụtụ isi hama n'akụkụ gburugburu nke billet. Isi hama na-agbagharị gburugburu axis mgbe ọ na-eme ụdị radial ugboro ugboro na workpiece, na-ebelata nha nke billet ma na-agbatị axial iji nweta ọrụ ahụ. Ma e jiri ya tụnyere osisi siri ike ọdịnala, ọnụ ahịa mmepụta nke ogwe oghere agbakọtara agbakọtara ga-abawanye ihe dị ka 20%, mana ibu nke ogwe moto ga-ebelatakarị site na 30-35%.

Oge ozi: Sep-15-2023